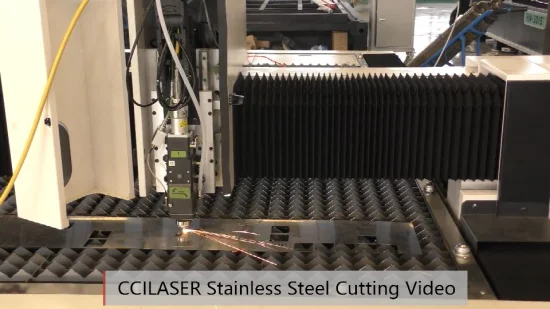

Full Enclosed Mini 1kw 1000W 1500W 1.5kw Small Gold Fiber Laser Cutting Machine CNC for Stainless Carbon Metal Sheet

Package Size 450.00cm * 225.00cm * 200.00cm Package Gross Weight 3500.000kg Lead Time 15 days (1 - 1 Sets) To be negotia

Basic Info.

| Model NO. | FLC6060-1000W |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Applicable Material | Metal |

| Structure Type | Gantry Type |

| Laser Classification | Solid Laser |

| Laser Technology | Laser Control Fault Cutting |

| Transport Package | Wooden Pallet |

| Specification | 1500Kgs |

| Trademark | CCILASER |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 15 Sets Per Month |

Packaging & Delivery

Package Size 450.00cm * 225.00cm * 200.00cm Package Gross Weight 3500.000kg Lead Time 15 days (1 - 1 Sets)To be negotiated ( > 1 Sets)

Product Description

1. Feature:

1.1 The fiber laser has high electrical-to-optical conversion efficiency, with a conversion efficiency of more than 30%. The low-power fiber laser does not need to be equipped with a chiller. The use of air cooling can greatly save power consumption during work, save operating costs, and achieve the highest production effectiveness;1.2 When the laser is running, only electric energy is needed, and no extra gas is required to generate the laser, which has the lowest operation and maintenance costs;1.3 The fiber laser adopts semiconductor modular and redundant design. There is no optical lens in the resonant cavity and no start-up time. It has the advantages of adjustment-free, maintenance-free, and high stability, which reduces the cost of accessories and maintenance time. Unmatched by traditional lasers;1.4 The output wavelength of the fiber laser is 1.064 microns, which is 1/10 of the CO2 wavelength. The output beam is of good quality and high power density, which is very conducive to the absorption of metal materials. It has excellent cutting and welding capabilities, so that the processing Lowest cost1.5 The whole machine is optically transmitted by optical fiber, and does not require complicated light guide systems such as mirrors. The optical path is simple, the structure is stable, and the external optical path is maintenance-free;1.6 The cutting head contains protective lenses, which minimizes the consumption of expensive consumables such as focusing lenses;1.7 The light is exported through the optical fiber, which makes the design of the mechanical system very simple and easy to integrate with the robot or multi-dimensional workbench;1.8 After the laser is added with a shutter, it can be one device and multiple machines, through the optical fiber splitting, divided into multiple channels and multiple units to work at the same time, easy to expand the function, easy and simple to upgrade;1.9 The fiber laser is small in size, light in weight, movable in working position, and small in footprint;

2. Advantage:

1. Economy.The fiber laser cutting machine has no other expenses exception of the electricity and consumables in use. It only needs one person to be operated, and it can be easily processed by inputting the drawing into the program.2. Practicability: The fiber laser cutting machine cuts the workpiece with high precision, and can reach the accuracy within 0.02mm, which reduce the workload of personnel and shorten the delivery time. In addition, its processing materials and thickness are very wide, cutting stainless steel, copper aluminum, carbon steel and aluminum alloy and so on.3. Efficiency: Efficiency determines economic benefits, and the cutting speed of fiber laser cutting machine can reach 100 meters per minute.

3. Application:

Fiber laser Cutting Machine is mainly for fast cutting with high precision of carbon steel, stainless steel, galvanized steel, titanium alloy, gold, silver, aluminum, brass and other material.

4. Applicable Industries:

Widely applied in thin metal sheets cutting, such as hardware, electronic parts and components, instrument, precision mechanic, glasses, jewelry, sheet metal processing, etc.

5. Main Components

6. CCILASER Factory

7. CCILASER CERTIFICATE

8. CCILASER Quality Control System

9. Exporting Package and Delivery

10. Customer CareTo be continued..

Send to us